- CONCRETE

- PACKAGING

- PRECAST

CONCRETE

Concrete is a mixture of Portland cement, water, aggregates and admixtures; it has a plastic consistency when fresh and mechanical strength characteristics when hardened, which makes it an ideal material for construction.

Thus, for any type of project, we provide ready-mix concrete preparation, transportation, and pumping services. Ready-mix concrete, more than a product, is an integral package that represents a series of benefits for the user. These benefits are translated into product quality, mix traceability, qualified advice, time and transportation savings; all of which are reasons why it surpasses on-site concrete, providing greater cost benefits.

Depending on the type of project, whether it’s for foundations, sidewalks, columns, slabs, etc., ready-mixed concrete is automatically and simultaneously dosed in the mixers with the necessary concrete additives to provide better consistency and workability. This ensures compliance with user requirements. The concrete is then transported in suitable concrete trucks. Additionally, for concrete discharge in elevated or hard-to-reach areas, concrete pumping is provided using concrete pumps with telescopic arms that have a vertical reach of 40 meters.

The designs are made according to the needs of our clients and comply with the Peruvian technical standards (NTP) and ASTM.

- READY-MIX

- SHOTCREeTE

READY-MIX

Concrete is a mixture of Portland cement, water, aggregates and admixtures; it has a plastic consistency when fresh and mechanical strength characteristics when hardened, which makes it an ideal material for construction.

Thus, for any type of project, we provide ready-mix concrete preparation, transportation, and pumping services. Ready-mix concrete, more than a product, is an integral package that represents a series of benefits for the user. These benefits are translated into product quality, mix traceability, qualified advice, time and transportation savings; all of which are reasons why it surpasses on-site concrete, providing greater cost benefits.

Depending on the type of project, whether it’s for foundations, sidewalks, columns, slabs, etc., ready-mixed concrete is automatically and simultaneously dosed in the mixers with the necessary concrete additives to provide better consistency and workability.

This ensures compliance with user requirements. The concrete is then transported in suitable concrete trucks. Additionally, for concrete discharge in elevated or hard-to-reach areas, concrete pumping is provided using concrete pumps with telescopic arms that have a vertical reach of 40 meters.

The designs are made according to the needs of our clients and comply with the Peruvian technical standards (NTP) and ASTM.

TYPES OF CONCRETE

We have a wide range of concrete types for different uses and applications:

- Conventional Concretes.

- Special Concretes.

- Concrete for Pavements, etc.

The most commonly used are:

Commonly used in construction made with selected aggregates and admixtures that allow to obtain a homogeneous and durable product.

Uses:

- Most common concrete structures: foundations, columns, walls, roofs, floors, sidewalks, among others.

Specially designed to be propelled (pumped) under pressure through a pipeline, allowing it to reach great horizontal and vertical distances.

Uses:

- Structures with considerable vertical (height) and horizontal distances.

- Structural elements that requires quick and efficient pouring.

- Structures with difficult access and limited spaces.

Specially designed with high fluidity to facilitate placement in elements that require it.

Uses:

- Concrete pumping at high altitude.

- Elements with high reinforcing steel confinement.

- Slender or difficult to access elements.

With a low water-cement ratio, it meets the requirements for early-age strength at 3 or 7 days.

Uses:

- Elements that require early removal of formwork or early service.

Designed considering the exposure and service conditions of the project. Its physicochemical properties increase the lifespan of structures.

Uses:

- Elements exposed to chloride and sulfate attack.

- Elements exposed to freeze-thaw conditions.

- Elements requiring low permeability.

- Elements exposed to acid attack.

SHOTCRETE

Process by which high-velocity compressed concrete is sprayed to form structural and non-structural elements in buildings. The mixture used is relatively dry and is consolidated by the force of impact. Its main applications include:

- Supporting and lining tunnels. Slope stabilization.

- Swimming pool lining.

- Tank lining.

- Lining of curved or warped structures.

- Masonry coating for protection or finishing.

- Reinforcements for concrete structures.

- Structural repairs.

PACKAGING

Concretos Supermix produces and markets bagged dry concrete, mortar (for masonry and finishing), and aggregates for construction. These products are made with the finest raw materials and high-quality standards using semi-automatic machines to meet the needs of our customers.

- MORTERO-A DE ALBAÑILERÍA

- MORTERO-T PARA TARRAJEO

- CONCRETO SECO

- PACKAGED AGGREGATES

MORTERO-A DE ALBAÑILERÍA

MORTERO de Albañilería Supermix, is a uniform mixture of appropriate proportions of YURA cement, high-quality sand, and additives. During its manufacturing process, it adheres to the highest standards and undergoes strict quality control, both in terms of its ingredients and its dosage, in compliance with ASTM C 387 standards.

APPLICATION

Concreto Seco Supermix is designed for use in slabs, foundations, columns, beams, and footings. It is formulated specifically for the installation of masonry units such as concrete blocks, bricks, etc., whether they are structural or for partition walls.

INSTRUCTIONS FOR USE

- Pour 3 liters of drinking water into a container and add the contents of the package, then add approximately 04 liters of water.

- Mix evenly until a homogeneous and plastic mortar is obtained.

- Clean the surface (free of dust, oil, paint, or other contaminants) and moisten the masonry unit before applying the mortar. Depending on the characteristics of the masonry unit, the specifications of the project regarding the setting of that unit should be followed.

- It is recommended to start curing with water from the next day after placement and continue for 72 hours. Respect the project specifications.

- Do not add more water after the initial mixing.

ADVANTAGES

- Ready to use product, just add water.

- Constant quality, pre-dosed, homogeneous mixture and excellent workability.

- Excellent adhesion, does not sag and provides a better finish to the joint.

- Accurate mixing, higher performance than on-site mixing.

- No need to purchase construction materials separately.

- Less waste, achieving more order and cleanliness in the construction site.

- Easy to transport and store. Stackable bags, saving space.

- Facilitates cost estimation and improves inventory control.

MORTERO-T PARA TARRAJEO

MORTERO-T para Tarrajeo Supermix, is a uniform mixture of appropriate proportions of YURA cement and high quality sand. In the elaboration process, it has the highest standards and a strict quality control, both in its ingredients and in its dosage, in compliance with the ASTM C 387 Standard.

APPLICATION

Specially formulated for the finish of walls and ceilings for both interior and exterior environments.

- Finishing.

- Rendering.

- Wall plastering.

INSTRUCTIONS FOR USE

- Clean the application surface (free of dust, oil, paint or other contaminants) and moisten before applying the mortar.

- Only use potable water in the amount required for the mixture in order to achieve a homogeneous, lump-free and workable mix.

- When pouring the water into the container, verify that there is no loss of liquid, as this affects the final characteristics of the product.

- Once the mortar is mixed, it should be applied within 20 minutes.

ADVANTAGES

- Ready to use product, just add water.

- Constant quality, pre-dosed mixture of great workability and economy.

- Excellent adhesion, does not sag and provides a better finish to the joint.

- Accurate mixing, higher performance than on-site mixing.

- No need to purchase construction materials separately.

- Less waste, achieving more order and cleanliness in the construction site.

- Easy to transport and store. Stackable bags, saving space.

- Facilitates cost estimation and improves inventory control.

CONCRETO SECO

Concreto Seco Supermix is a dry and homogeneous mix, composed of cement, gravel and sand with controlled granulometry, whose proportions vary according to the concrete specifications. The reduced humidity of the components of the mix guarantees that the bagged cement does not react, thus increasing the shelf life of the product.

APPLICATION

Concreto Seco Supermix is designed to be used in slabs, foundations, columns, beams, footings, etc.

PREPARATION

Just add water to obtain a concrete acceptable to your needs.

ADVANTAGES

- Ready to use product, just add water for the required consistency.

- Accurate mixing, higher performance than on-site mixing.

- Easy to transport. Its packaging allows it to be transported in any vehicle.

- Less waste, achieving more order and cleanliness in the construction site.

- Easy storage. Stackable bags. Saves space and improves inventory control.

- Greater order and cleanliness on site.

- Increased labor efficiency. Reduction of project execution time.

- We manufacture concrete of any strength according to requirements.

TECHNICAL INFORMATION

- Compressive strength: We manufacture dry concrete of any type of strength, according to the client's requirements.

- Application temperature: From 10° C to 32° C.

- Amount of water: The amount necessary to obtain a pasty mix, being able to be from 4.5 - 5.0 liters per bag.

- Each bag of Concreto Seco Supermix weighs 40kg.

STORAGE

To keep Concreto Seco Supermix in optimal conditions, it is recommended:

- Store in a dry environment, under cover, away from the floor and walls.

- Protect them against humidity or humid air currents.

- In case of prolonged storage, cover the dry concrete with polyethylene.

- Do not stack more than 8 bags high.

RECOMENDACIONES

- The water will be placed in the following way: 2/3 parts at the beginning, then enter the dry mixture and at the end 1/3 part of the water.

- The mixing time shall be 3 to 5 minutes to achieve a homogeneous mix.

- The concrete should be poured within 30 minutes of the end of mixing to guarantee the quality of a fresh and hardened concrete.

PACKAGED AGGREGATES

In order to provide quality products to our clients, we offer aggregates that comply with NTP 400.037 and ASTM C-33. With adequate granulometries according to the client’s needs.

WE HAVE

- Coarse Sand

- Stone of 1", ½", ¾" and 3/8".

PRECAST

PERIMETER FENCE - POST AND PANEL

The concrete post provides the anchor to accommodate the precasted fence panel. It is easy to install.

Dimensions:

- Outside dimensions 150 x 150 x 3700 mm

- Outer wall thickness of wall housing: 60 +- 2mm

- Inner wall thickness of wall housing: 50 +- 2 mm

- Resistance: 21 Mpa (175 kg/cm2) at 28 days.

- Standard: NTP 339.033

- Test: NTP 339.034

- Weight: 168+/- 0.5 kg.

- Color: Natural gray.

PERIMETER FENCE - CONCRETE PANEL

It is used for the construction of the prefabricated wall and is embedded into the face of the post. It is easy to install.

Dimensions:

- Outside dimensions: 2310 x 400 x 50 mm

- Wall thickness: 50 +- 2mm

- Strength: 17.5 Mpa (175 kg/cm2) at 28 days

- Standard: NTP 339.033

- Test: NTP 339.034

- Weight: 115 +/- 0.5 kg.

- Color: Natural gray.

POTABLE WATER METER BOX

A concrete box that provides space to house the potable water meter and its accessories for connection to the home water supply line.

Dimensions:

- Outside dimensions: 550 x 330 x 200 mm

- Wall thickness: 40 +- 2mm

- Cover opening: 250 x 330 x 200 mm

- Water pipe opening (lxh): 140 x 120 +/- 2 mm

- Strength: 17.5 Mpa (175 kg/cm2) at 28 days.

- Standard: NTP 339.033

- Test: NTP 339.034

- Weight: 22.00 +/- 0.5 kg

- Color: Natural gray

VOUSSOIR

It´s a wedge-shaped segment of an arch that is bolted to its adjacent segments to form a complete ring and work together to withstand geomechanical stresses.

The infrastructure for production operations includes a 14 m wide by 136 m long building equipped with two 10-ton overhead cranes. It also features a 200BHP steam generator boiler and a compressor room with a capacity of 15,000 liters/minute. Adjacent to the building in the central area, there is a ready-mix concrete plant with a capacity of 40 m3/hr, which supplies the concrete for the production of the voussoir segments.

It has two lines or sets of molds of German technology (same manufacturer as the TBM) arranged longitudinally and consisting of 72 voussoir molds. The installed capacity allows for the production of 24 rings per day (624 rings per month) in a double shift. This manufacturing system is known as a fixed or stationary station.

SINGLE-PHASE METER POST

Concrete post that provides the necessary space to house the single-phase electric meter and its connection accessories to the house connection line.

Dimensions:

- Inside box dimension: 195 x 340 x 110 mm.

- Wall thickness: 130+- 2mm

- Total height: 1860 +- 2 mm

- Inner socket: 25.4 +/- 2 mm

- Strength: 17.5 Mpa (175 kg/cm2) at 28 days.

- Standard: NTP 339.033

- Test: NTP 339.034

- Weight: 110 +/- 0.5 kg

- Color: Natural Gray

Wheel Stops

Concrete tire stops that are easy to install, providing impact resistance for tires.

Dimensions:

- Installation socket: Diameter 195 mm

- Element thickness: 182 +- 2mm

- Total height: 122 +- 2mm

- Total length: 592 +- 2mm

- Strength: 17.5 Mpa (175 kg/cm2) at 28 days

- Standard: NTP 339.033

- Test: NTP 339.034

- Weight: 27.00 +/- 0.5 kg

- Color: Natural gray

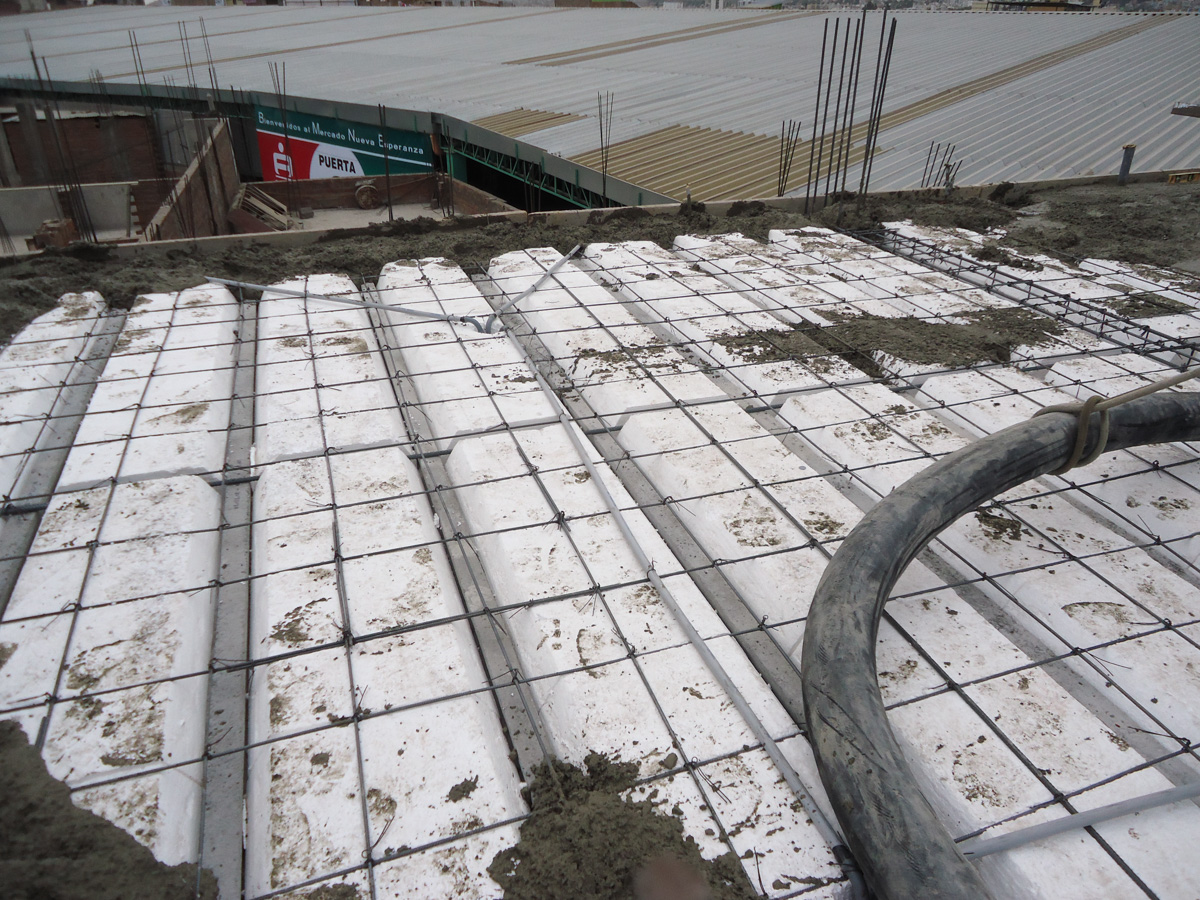

BEAM-AND-BLOCK

Supermix Beam-and-blocks are a complement to the pre-stressed beam slab system. They are placed between the beams, collectively covering the surface of the slab as a filler and eliminating the need for formwork.

They contribute to the lightening of the slab, as well as to the thermal and acoustic insulation, achieving greater safety and quality in this construction system.

Manufactured in modern vibro-compacting machines, with an automated dosing system of raw materials for the manufacture of vibro-compressed concrete products and with high quality controls, thus guaranteeing a high quality of the elements as well as a permanent stock made available to all clients.

PAVERS

The pavers are simple concrete pieces that have undergone a vibro-compaction process, ensuring a faster, more comfortable and safer transit, as well as being cost-effective and having a better behavior in case of rain.

Because of their beauty, aesthetics, variety of colors, resistance to wear and tear, ease of installation and maintenance, concrete pavers are a practical solution for the construction of streets, sidewalks, patios, gardens, etc.

Supermix concrete pavers are produced under Peruvian Technical Standard NTP 399.611.

PRODUCTION PROCESS

Supermix pavers are simple concrete pavement pieces, produced in automated plants with American technology equipped with control cabins and PLC boards, which monitor the entire industrialized production process.

An inclined belt conveys selected aggregate, which along with cement, water and admixtures, is batched and delivered to a concrete mixer.

This mixture is then transported to a vibro-compactor where the concrete paver molds that shape the product are located; the product is then transported on fresh metal plates to metal scaffolding where it will be taken to rooms where it will undergo a wet curing process for 24 hours to increase its initial strength, after which the product will be taken to storage areas.

BENEFITS

- Durability: It does not suffer from fractures in extreme temperature situations, offering a pavement without cracks. They have a longer useful life compared to other pavements.

- Strength: Resistant to different types of traffic (pedestrian, light and heavy vehicular, industrial). Supermix pavers have the strictest quality control to ensure their high resistance.

- Easy installation and reinstallation: They can be easily uninstalled and installed (reused) in another place, without losing their original characteristics. No skilled labor is required for installation.

- Safety and warranty: Supermix pavers have a non-slip surface, even when wet. They are also quality certified.

- Production Capacity: Our plants are prepared to meet the most demanding construction schedules in record time.

- Eco-friendly: Supermix pavers are manufactured with natural materials and without pollutants, and no chemical processes are involved in the paving process.

- Decorative: We offer a wide range of colors and shapes, which allows for a wide variety of designs and combinations.

CLASSIFICATION

BLOCKS

Used for decades as an element for all types of constructions, the traditional concrete block has evolved to previously unsuspected levels.

The great variety of shapes, sizes, textures and colors in which they are produced today, allow architects, engineers and builders to combine them to achieve spectacular aesthetic effects, with costs significantly lower than those of other materials.

MAIN APPLICATIONS

- Single-family houses.

- High-rise buildings.

- Shopping centers.

- Public buildings: schools, libraries, museums and health centers.

- Industrial buildings, complexes, factories, sheds, warehouses, etc.

- Ground support walls.

- Water cisterns

- Fire resistant barriers.

- Exterior and lower load-bearing walls.

- Enclosures of independent structures.

- Partition walls.

CLASSIFICATION

BENEFITS

- Modular coordination: Allows the use of whole pre-molded pieces, half blocks, blocks with central recess, L-type blocks, T-type blocks, textured blocks (stone type), saving time, materials, tasks, etc.

- Fewer units per m2: 12.5 exact units are needed to materialize 1 m2 of masonry.

- Higher labor efficiency: A bricklayer and his assistant can build about 12 m2 of wall per day (more than 150 blocks), including a structure composed of vertical and horizontal bars distributed on the wall and properly placed with concrete filler.

- Less mortar: Less mortar is needed to set 1 m2 of concrete blocks compared to clay bricks. In some cases, the concrete block can be left exposed on the inside, without the need for any surface treatment, while on the outside it requires an adequate waterproofing treatment either by applying traditional plaster, plastics or paints.

- High resistance to axial compression of the resulting wall: This property makes this construction system (reinforced masonry) widely used in seismic zones around the world.

- Thermal and acoustic insulation: It allows a design to achieve great thermal and acoustic insulation, since the blocks have perforations close to 50% of their gross area, providing an insulating air chamber for both factors, which can be filled with suitable materials.

- Rationalization of sanitary and electrical installations: By using concrete blocks of different thicknesses (widths), the use of concrete blocks allows for the creation of entrances and outlets in the wall, commonly known as niches, where the sanitary and electrical pipes are housed, without having to cut the concrete blocks with iron cutters or abrasive discs, as is the case with bricks, with their consequent labor demand, high waste of materials and generation of localized cracks.

- Flexibility of use: As a structural and constructive system, it is possible to design from low-cost low-income housing to high-rise buildings, as well as other uses such as industrial, commercial, hotel, hospital, educational, etc.

CONCRETE SLEEPERS OR TIES

Concretos Supermix S.A. owns the first automated concrete sleeper plant for railways in Peru. Concretos Supermix manufactures sleepers based on Italian and proprietary technology, complying with international AREMA standards. The sleepers are produced through a rigorous manufacturing process that ensures durability and quality to withstand significant dynamic load efforts of up to 30 tons per axle. The sleeper plant has a production capacity of up to 800 units per day.

They offer design alternatives that can meet different types of requirements, providing safety and comfort for users.

Sleepers are structural elements placed transversely on the ballast, distributing the wheel load across the track. In addition to supporting the rails, they maintain the separation between them, providing a means for the rails to stay securely at the correct distance from the scantling.

Sleepers can come in various types, with concrete sleepers having a lifespan of over 30 years.

BENEFITS

- Greater durability: Concrete is a durable and homogeneous material that resists the action of atmospheric, climatic, and organic agents. Concrete has a lifespan of over 30 years.

- Low maintenance cost: Concrete sleepers require practically no maintenance, which means substantial savings in labor, equipment and machinery.

- High safety: Concrete sleepers are designed to provide both rigidity to ensure track stability and flexibility to absorb repeated shocks caused by passing trains, reducing the risk of derailment.

- User comfort: Concrete sleepers have a uniform and homogeneous quality, which results in lower noise levels for the user and less oscillation inside the cars.

- Ease of operation: Due to their uniformity, their manufacturing process and the materials used, the sleepers guarantee the quality of the element in kilometers of track. Likewise, they easily replace wooden sleepers.

- Economy: Concrete sleepers provide greater support to the train, which translates into greater speed, saving energy and time. They also increase the useful life of the cars and allow a greater load per axle. As it is a world-class domestic product, there are no import costs, no customs procedures, and no inventory maintenance costs.

- Reduced environmental impact: Preserving native forests is fundamental for the ecosystem. The felling of native wood such as coigue, ulmo, tineo, quebracho, tepa and oak, used for the manufacture of sleepers, represents an unnecessary environmental degradation.

- Technical support: We have a team of highly trained professionals to provide qualified technical assistance.

TECHNICAL FEATURES

- Maximum axle load: From 20 Ton. Up to 30 Ton.

- Gauge: Standard, metric and upon customer’s request.

- Type of Rail: 90 ARA – 115 RE

- Fastening: Pandrol type-Eclip and upon customer’s request.

- Sleeper weight: From 250 Kg. To 325 Kg.

- Resistance to compression: 500 Kg/cm2

- Resistance to transfer fct: 300 Kg/cm2 (at 10 hours)

- Rail inclination: 01.40 and upon customer’s request.

- Standard: Arema and Alaf

PRESTRESSED JOISTS

Supermix prestressed joists are an industrialized product for construction, designed to be used in all types of lightened slabs, significantly reducing structural weights, favoring the building with a lower basal shear stress that favorably affects the response to an earthquake. Significantly reduces construction execution times, resulting in lower construction costs.

BENEFITS

The materials used for the manufacture of the prestressed joist are of far superior characteristics to those manufactured on site with conventional concrete.

The Supermix prestressed joist is designed to generate a perfect adherence with the concrete of the slab and to generate a lock that allows to consolidate a greater rigidity and stability of the whole element.

They are used in all types of slabs as an easy-to-install structural element, which reduces the weight of the structure and allows for a considerable reduction in the time required for the execution of the construction project.

Significantly reduces labor costs in formwork. It also reduces the volume of concrete slab.

TECHNICAL FEATURES

- Mezzanine slabs.

- Roof slabs.

- Enclosure vaults.

- Pedestrian walkways.

- Parking buildings.

- High-rise buildings.

- Buildings starting from 2 floors.

They are used in all types of slabs as resistant elements, significantly reducing structural weights and facilitating the placement of the slabs, significantly reducing construction execution times and lowering labor costs.